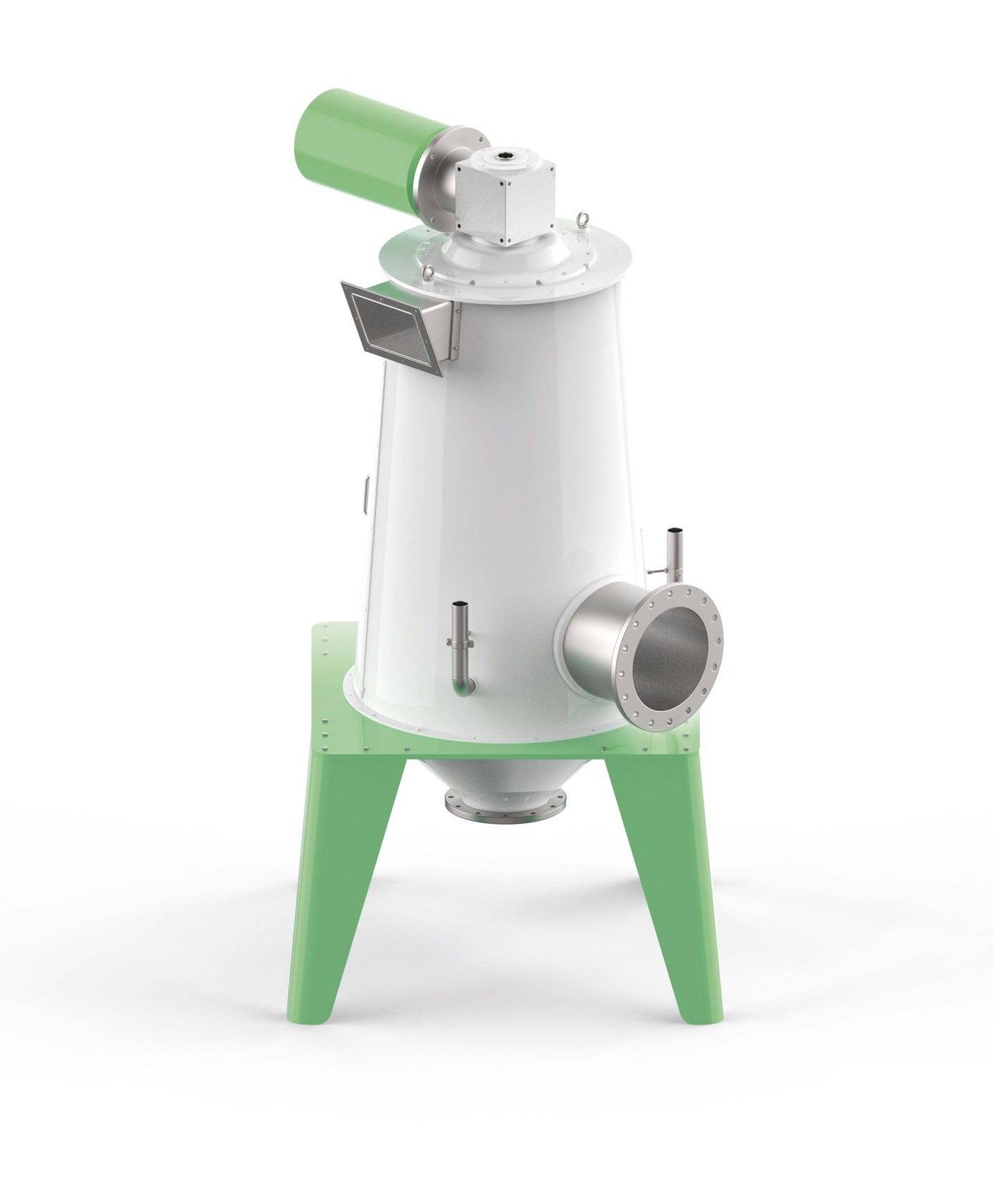

Separators: VS-Series

Our Separators technology at a glance

With their vertical construction the new VS series’ separators are designed for separating large quantities of packaging and foodstuffs. They open and shred the packaging without generating any harmful microplastics. What remains as an end product is clean with a > 99% degree of purity. This enables en economical and sustainable return of raw materials to the natural cycle.

A powerful electric motor provides a throughput of up to 24m³ per hour.

Packging is torn up by rotating paddels. Heavier organic contents are separated from the lighter packaging by centrifugal and gravitational force.

What remains in the end is > 99% pure bio substrate with a controllable water content for optimal use in biogas plants

Separators compare models a glance

Separation-technology patented without compromise

Models

Output

Screen diameter

Height

Weight

Rotation speed

Connection values

Filterroutles

VS400

Up to 10 m³ / h

480 mm

2.700 mm

1.500 kg

900 – 1450 rpm

22 – 55 kW

6 – 20 mm

VS600

Up to 15 m³ / h

680 mm

3.300 mm

1.850 kg

900 – 1450 rpm

22 – 55 kW

6 – 20 mm

VS900

Up to 24 m³ / h

880 mm

3.900 mm

3.000 kg

900 – 1450 rpm

22 – 55 kW

6 – 20 mm